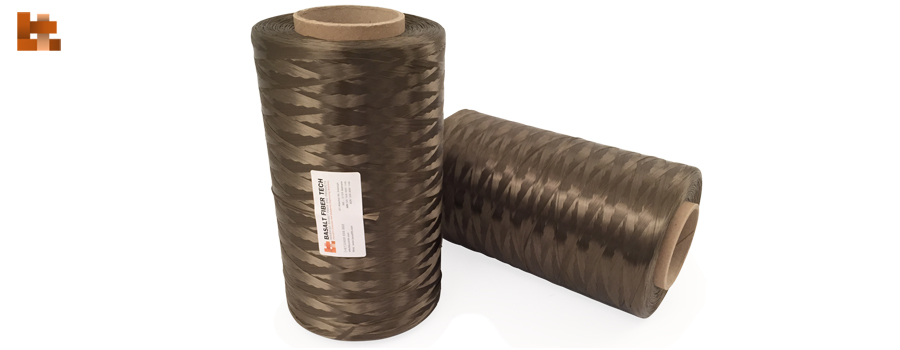

Assembled Roving

Basalt Continuous Filaments under the name of Basfiber®

General Description:

Assembled Roving is a multi-end continuous roving. The strands of different spinning cakes are gathered into a single strand and wound into a cylindrical package without twist. Assembled roving consists of some strands drawn at the facility for production of continuous basalt fiber and then assembled together at assembling machines. Assembled roving can be produced at the bobbins of internal or external unwinding depending on customer requirements.

-

Nomenclature

Our nomenclature is based on three letter followed by three numbers split by dot and dashes.

Example:RAS-13.1200-11

The first letter will be always R which stands for our Rovings products. The following letters AS - GN - DR represent the roving type:

AS - Assembled Roving: External unwinding bobbin roving with on a tube or Internal unwinding (tubeless).

GN - Gun Roving: Internal unwinding (tubeless)

DR - Direct Roving: Direct Unwinding -

Tex Info

Tex of assembled roving is determined by:

- Fiber's monofilament diameter;

- Number of monofilaments in strand (i.e. number of nozzles in bushing);

- Number of strands in assembled roving which is limited by number of places at the creel and acceptable level of catenary which is getting worse with increasing of number of strands in assembled roving.

In our opinion, it is not wisely to use assembled roving which consist of more than 10 strands assembled together. Mechanical tests show 30% difference of tensile strength between assembled rovings consisting of 4 and 20 strands due to increased catenary.

-

Applications:

- Boat shells,

- Storage tanks,

- Pipes,

- Automotive parts;

- Construction application;

- High pressure vessels;

- CNG cylinders;

- Boat building;

- Bridge profiles;

- Concrete reinforcing bars;

- Fabrics for sound and heat insulation;

- Corrosion applications.

-

General Properties

Property Description Type of fiber Basfiber® Monofilament diameter [µm] From 10 to 22 Linear density [tex] 270-4800 Type of sizing 11, 12, 13, 15 and 42. Sizing content (% wt.) ≥0.4 Resin compatibility Polyester, vinyl ester, epoxy Moisture content (% wt.) <0.1

Thermal Properties Melting Range: 1460-1500°C Crystalization temperature: 1250°C Sintering Temerature: 1050°C Thermal Conductivity, W/(múK) 0.031-0.038

Tensile Strength Change by heating Basfiber® Temperature +20°C +200°C +400°C Tensile Strength Change 100% 95% 80%

Mechanical Properties:

| Nomenclature | Monofilament diameter, µm | Linear density, tex (g/km) | Tensile strength, MPa ASTM D2343 | E-modulus, GPa ASTM D2343 | Tensile strength, mN/tex ASTM D3822 |

|---|---|---|---|---|---|

| RAS-10.270 | 10 ±0.5 | 270 ±5.0% | 3000-3200 | 85-90 | ≥700 |

| RAS-13.300 | 13 ±0.5 | 300 ±5.0% | 3000-3200 | 85-90 | ≥650 |

| RAS-13.600 | 13 ±0.5 | 600 ±5.0% | 3000-3200 | 85-90 | ≥650 |

| RAS-13.1200 | 13 ±0.5 | 1200 ±5.0% | 3000-3200 | 85-90 | ≥650 |

| RAS-13.2400 | 13 ±0.5 | 2400 ±5.0% | 3000-3200 | 85-90 | ≥650 |

| RAS-17.1200 | 17 ±1.0 | 1200 ±5.0% | 2800-3000 | 85-90 | ≥600 |

| RAS-17.2400 | 17 ±1.0 | 2400 ±5.0% | 2800-3000 | 85-90 | ≥600 |

| RAS-17.4800 | 17 ±1.0 | 4800 ±5.0% | 2800-3000 | 85-90 | ≥600 |

| Other Mechanical Properties: | Chemical Stability | |||||||

|---|---|---|---|---|---|---|---|---|

| Monofilament diameter, µm: | 10 | 13 | 17 | Weightlessness: | Cem FIL | Basfiber® | E-glass | |

| Tensile test ASTM D-3822: (Dry fiber) Tensile strength, mN/tex | ≥700 | ≥ 650 | ≥ 600 | 3-hour boiling in water | - | 0.20% | - | |

| Tensile test ASTM D-2343: (In epoxy impregnated strand) tensile strength, MPa | 3200 | 3100 | 2900 | 3-hour boiling in saturated cement solution (pH 12,9) | 0.15% | 0.35% | 4.50% | |

| Tensile test ASTM D-2343: (In epoxy impregnated strand) tensile modulus, GPa | 90-94 | 88-92 | 86-90 | 3-hour boiling in 2N solution HCl (hydrochloric acid) | - | 2-7% | 38.50% | |

| Tensile test ASTM D-2101: (Basalt monofilament)tensile strength, MPa | 4300 | 4200 | 4000 | 3-hour boiling in 2N solution NaOH (sodium hydroxide) | - | 6% | - | |

| Tensile test ASTM D-2101: (Basalt monofilament) tensile modulus, GPa | 95 | 93 | 92 | 30 minutes and in 180 minutes in H2SO4 (sulphuric acid) | - | 2% - 6% | 14% - 22% | |

Sizing Compatibility

| No. of Sizing | Type | Compatibility | Sizing content, % Weight | Moisture, % Weight | Single-End | Multi-End |

|---|---|---|---|---|---|---|

| 10 | Silane | EP, PF, PP*, acrylate, PA | 0,4-0,8 | <0,1 | 10-22 µm, 90- 600 tex | 10-22 µm, 270- 4800 tex |

| 11 | Silane | UP, VE, EP | 0,4-0,8 | <0,1 | 10-22 µm, 90- 600 tex | 10-22 µm, 270- 4800 tex |

| 12 | Silane | EP, PF | 0,4-0,8 | <0,1 | 10-22 µm, 90- 600 tex | 10-22 µm, 270- 4800 tex |

| 13 | Silane | concrete, EP, PF, acrylate | 0,4-0,8 | <0,1 | 11-19 µm, 90- 750 tex | 13-17 µm, 300- 4800 tex |

Thermal Properties:

| Thermal operation range of Basfiber® | |

|---|---|

| Thermal load duration | Temperature range |

| Permanent | From -260 up to +400°CC |

| (1) Stage 1: amorphous fiber with sizing on the fiber surface | Up to +200°C |

| (2) Stage 2: burning of sizing (10-15 minutes), amorphous fiber | From +200 up to +350°CC |

| (3) Stage 3: amorphous fiber without sizing on the fiber surface | From +350 up to +400°CC |

| Short term (few minutes) | From +400 up to +850°CC |

| (4) Stage 4: transition of FeO into Fe2O3 and beginning of crystallization | From +400 up to +850°CC |

| Short term (few seconds) | From +850 up to +1250°CC |

| (5) Stage 5: all the Fe2O3 is in crystal form, the material is extremely brittle, its mechanical properties are extremely poor but without stress and vibration it continues working as thermal insulation pretty good | From +850 up to +1050°CC |

| (6) Stage 6: sintering temperature | From +1050 up to +1250°CC |

Packaging

Rovings are supplied on a 120x80 cm pallet with 2-4-6 layers, each bobbin wrapped in thermal retractable film.

| Linear Density, Tex | Diameter | Height | Net Weight Bobbin, Kg | |||

|---|---|---|---|---|---|---|

| 90 | 200mm | 255mm | 3 | 4 | - | - |

| 110-350 | 200mm | 255mm | 3 | 4 | 5 | - |

| 350-840 | 200mm | 255mm | 3 | 4 | 5 | 8 |

| On a 4-layered pallet could be supplied | 60 bobbins ca. 180 kg | 60 bobbins ca. 240 kg | 56 bobbins ca. 280 kg | 44 bobbins Ca. 352 kg | ||

| On a 6-layered pallet could be supplied | 90 bobbins ca. 270 kg | 90 bobbins ca. 360 kg | 84 bobbins ca. 420 kg | 66 bobbins ca. 528 kg | ||

| Bobbin SE-, AE-roving | 76mm | 260mm | 3 | 5 | - | 9 |

| Tube by SE - roving | 76mm | 270mm | 3 | 5 | 8 | - |

| On a 4-layered pallet could be supplied | 192 bobbins ca. 576 kg | 140 bobbins ca. 700 kg | 96 bobbins ca. 768 kg | 88 bobbins ca. 792 kg | ||

Download Data Sheet

| Download Assembled Roving Technical Data Sheet in .PDF: |  |

| Download Assembled Roving Material Safety Data Sheet - MSDS in .PDF: |  |

| Download our Basalt Continuous Filaments Sizing List in .PDF: |  |

Contact Us