Structural Strengthening

Basfiberwrap® the product range of Basfiber® for strengthening of new and old structures.

Basalt Fiber Tech structural reinforcement for a variety of applications in the construction industry. Basfiber® fabrics are Natural, Fire Resistant, high mechanical properties (strength and rigidity).

- Costs less.

- Requires less installation time.

- Lasts longer.

- Does not change original features of structure, i.e., (univasive).

- Requires minimal access for installation.

- Adds only an eighth of an inch to the thickness of the original structure, preserving floor space.

- Does not add to the weight of the structure.

- Adds significant strength and ductility to the structures, without adding mass.

Concrete Beams:

Basfiberwrap® can increase flexural and shear strength of concrete beams. For flexural strengthening, Basfiberwrap® is bonded to the tension face. For shear strengthening, Basfiberwrap® is bonded to the web of the beam.

-

-

- Increases flexural strength.

- Increases shear strength.

- Does not reduce overhead clearance.

- Light-weight and easy to install.

- Costs less than alternatives.

Steel Beams:

Basfiberwrap® is used to increase strength and to repair cracked steel girders. The full capacity of cracked girders can be restored by bonding Basfiberwrap® to the girder. Millions of fatigue cycles of the repaired girders showed no distress or de-lamination of the Basfiberwrap® from the steel.

-

-

- Restores full capacity of cracked girders.

- Increases flexural capacity n Increases fatigue life.

- Eliminates stress concentration and residual stresses due to welding.

- Increases stiffness.

- Costs less than alternatives.

Concrete Columns:

Basfiberwrap® is used to increase ductility and strength of concrete columns. Due to the beneficial effects of confinement, the column ductility is significantly increased. In addition, Basfiberwrap® helps to make up for inadequate amount, or improperly detailed lateral ties and increases the shear strength of the columns significantly.

-

-

- Increases ductility.

- Increases shear strength.

- Increases axial load carrying capacity.

- Light-weight and easy to install.

- Can be wrapped along columns with varying cross section.

- Costs less than alternatives such as steel jacketing.

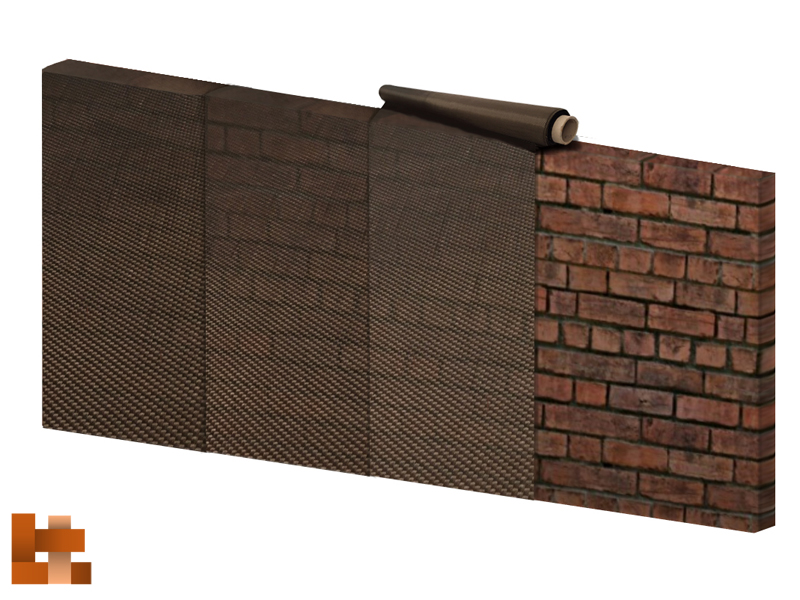

Concrete Masonry and Brick Walls

Basfiberwrap® significantly increases the in-plane and out-of-plane strengths of un-reinforced masonry and brick buildings. It is very light-weight and is applied to this type of structure in a manner similar to wallpapering, but at the same time it provides significant strength as if shotcrete had been applied to the structure. The salient benefits of Basfiberwrap® for this application include:

-

-

- Increases out-of-plane flexural strength.

- Increases in-plane shear strength.

- Adds insignificant weight to the existing structure.

- Requires no foundation modification, since it does not add to the weight of the structure.

- Basfiberwrap® is less than 1/8 inch thick and therefore, does not result in any loss of floor space. Basfiberwrap® converts a brittle, unreinforced masonry structure into a reinforced and ductile structure by making all masonry units work together.

- Fast and easy to install.

- Costs less than alternatives such as shotcrete.

Concrete Slabs

Basfiberwrap® fabrics or strips are bonded to the bottom of slabs (positive moment regions) or to the top of the slab (negative moment regions) to increase flexural capacity.

-

- Increases flexural strength.

- Reduces deflections.

- Light-weight and easy to apply.

- Protects slab from further environmental damage.

- Costs less than alternatives.

Concrete Pipes

One of the most effective and economical applications of is in strengthening of buried pipes. Concrete and steel pipes can be strengthened to take pressures even greater than that of their original design value at a fraction of the cost and time of alternatives. In the case of 3 foot and larger diameter pipes, simple access is made through the manholes and all operations are conducted internally. If the pipe can be accessed from the outside, the wrapping can be performed on the outside face of the pipe; resulting in the same benefits.

Steel Pipes

Corroded or leaking steel pipes can be strengthened to make up for the lost thickness due to corrosion by using Basfiberwrap®. This application also fully water proofs the pipe and prevents leaking. Steel pipes can be strengthened to take pressures higher than that of their original design value.

Protective Coatings

Basalt Fiber Tech wrap line of products offers state-of-the-art systems for protection of steel and concrete structures in caustic environments. Basfibercoat® systems effectively increases the life of structures by providing a complete protection against detrimental effects of some of the most caustic chemicals in industrial settings, such as petrochemical, mining, chemical processing, water and waste treatment facilities, etc. Thousands of square meters of structures have been coated with Basfibercoat® systems, providing unsurpassed protection to structures.

Advantages for Pipes

- Requires no excavation.

- Increases pipe strength to even higher than its original pressure rating.

- Access is made only through manholes.

- Creates a very smooth surface and improves pipe flow significantly.

- Basfiberwrap® inside the pipe is about one-eighth of an inch thick, therefore, it does not reduce the inner diameter and flow volume of the pipe.

- Light-weight: requires no heavy equipment for installation.

- Costs far less than the alternatives and results in speedy construction.

Contact Us