Basalt Fiber Non-Woven

Neddle punch non-woven under the name of Basfibermat®

General Description:

A new noncombustible heat insulation material- Basfibermat®. This product allows to realize the main advantages of the basalt fiber over the traditional fibers - E-glass and mineral wool. The continuous temperature application rates about 300°C higher than the comparative product made from E-Glass. The final application, its environment, the heat conditions, the heat directions, the density of the mat itself, as well as its thickness are only a few determining factors for the appropriate continuous application temperature. It seems that a good safe number will be 1000°C for the Basfibermat®. Higher values may apply, depending on the particular application.In order to enhance temperature reflective properties, an aluminium foil can be added to the product. While the Basfibermat® is widely used in thermal applications, it also can be treated with resins and turned into a constructional board.

Automotive Industry:

Automotive industry from thermal insulation material requires the following:

- Compactness:That is why several types of thermal insulation wools are being pressed to make them usable in this area;

- Resistant to Aggressive environment: It is essential that aggressive car smokes or liquid drops were not able to harm technical parameters of the car;

- Amplitude of Sound Absorption To reduce discomfort that it may cause to the passengers or outside environment;

- Compliance with modern Fire Resistant Norms: Does not burn, does not produce poisonous substances and does not deform or does not incur surface shrinkage in fire conditions;

Consequently its technical parameters makes the Basfibermat® the most desired sound and thermal insulation material in automotive industry.

Industrial Insulation

Usage of Basfibermat® in industrial technologies for insulation of industrial heat-tracks is exceptionally effective due to a number of technical data, in particular because of its compactness (high density >150kg/m³ ) and low thermal conductivity coefficient, it is available to create low thickness thermal insulation layer and reach serious economy of metal casing. In many cases 2-3 times less metal casing is needed, than in case of using ordinary type thermal insulation materials. Economic effect is more as the diameter and temperature, on which industrial heat-track works, rises. The number of emergency situation that are caused by water steam launches decreases in case of using Basfibermat® , as it does not saturate. (Humidity <1%). As the temperature of insulated material rises, coefficient of thermal conductivity decreases in comparison with the other insulation materials (see table) and accordingly significantly less amount (low density <80 kg/m³) of Basfibermat® is needed in comparison with other wool type insulation materials to reach the same effect.

Walls

Based on exceptional thermal insulation characteristics of Basfibermat® it is able to create light weighted house wall design. This material creates an opportunity to eliminate costs of thermal insulation works; to build wall fast and to be light weighted; to use inside wall space not only for creating electrical wiring, but also to place water, sewerage and heating pipe systems and in case of needed re-installation process can be accomplished fast and with low costs (without any processes of demolition). In the wall system it is important to use fire resistant thermal insulation material; it can be very effective in case of hazards in electric wiring system. Usage of Basfibermat® also eliminates diffused water vapour condensate creation inside the wall.

Floors

In floor heating systems it is recommended to use mat with foil, because of below two arguments: 1. In under floor heating systems as non-rotting and little thermal conductivity thermal insulation material will drive thermal losses to minimum in the lower part of floor heating systems. Foil attached to mat reflects additional thermal radiation. Therefore Basfibermat® in combination with foil gives an opportunity no to lose generated energy and fully use it for heating of floor surface. 2. Using Basfibermat® between floor thermal insulation is not only effective for its ability to created thermally isolated space, but also as sound isolation material. Moreover compliance with fire resistance standards makes the product as one of the most desired products in terms of usage for living spaces, as always exists the probability of hazards in electrical - wiring system Flame/ Heat barrier constructional Board.

Comparison with Glass Wool:

Thermal Conductivity (W/m2k) with 5% tolerance Average Temperature (°C) 20° 100° 200° 300° 400° 500° 600° 700° Basfibermat Density: 130 kg/m2 0.031 0.034 0.042 0.056 0.08 0.115 0.161 0.2 150 kg/m2 0.031 0.033 0.041 0.054 0.078 0.115 0.154 0.209 170 kg/m2 0.031 0.032 0.039 0.053 0.075 0.105 0.143 0.191 Glass Wool 0.039 0.056 0.063 0.079 0.118 Loses Characteristics Thermal Proprieties Basfiber® Glass Wool Application Temperature (°C) -260° to +700° 350°-500° Short-term Max-Operation Temperature (°C): +850° +550° Heat Conductivity (W/m2k) 0.031 to 0.038 0.034-0.04 Mechanical Proprieties Basfiber® Glass Wool Tensile Strength of dry Fiber - mN/tex

(ASTM D3822)600-730 350-500 Tensile Strength of single filaments - MPa

(ASTM D2101)4500-4800 3450-3800 Tensile Modulus of single filaments - GPa

(ASTM D2101)84-87 72-76 Water pipe systems

For water pipe systems in conditions of thermal insulation is following type of event: periodic change of water temperature that is technologically ordinary event for this kind of systems. It is natural that this event causes creation of water condensate on outside surface of the pipe. In this case it is essential to use the thermal insulation material that does not get wet (in other words, does not lose its thermal insulation ability) and does not decompose in water (does not rot, so can function in long term). For this exceptional characteristics (does not get wet, does not decompose through time) Basfibermat® is one of the most desired material for water pipe systems thermal insulation.

Shipbuilding

Final selection of insulation materials for shipbuilding has always been a difficult task, as this material should be compact (In the limited space less volume is available for insulation); comparatively mechanically solid (Flexible, elastic, resistant to attack); resistant to aggressive sea environment (should be acid and alkali resistant); Functional in exceptionally high moisture environment (Does not collapse in water and does not rot); Able to function in high temperatures and correspond to fire resistance norms (>-18°C >+650°C). Exactly this kind excellent insulation material is Basfibermat® , as with its technical characteristics, it satisfies all essential conditions listed.

Roofs

Lowest coefficient of thermal conductivity (0.031 W/mK) and high density (>150 kg/m³) gives opportunity to consumers to easily resolve thermal insulation issue while creating building roofing. Moreover, simple roofing design eliminates additional costs associated with installation and is defined for long term usage - in case of water or condensate influence, does not get wet or disband. Basfibermat® is fire resistant thermal insulation material that is in compliance with ASTM C392 standard.

Other Applications:

- Flexible Expansion Joints

- Gaskets

- Batting

- Asbestos replacement

- Cryogenic

- Ovens

- Furnaces

- Turbines

- White ware

Other Properties:

- Non-respirable, 13 micron filament diameter.

- Meets chemical acceptability of NRC Guide 1.36, section C

- Very high alkali and acid resistance (surpassing most mineral and synthetic fibers)

- Negligible moisture absorption (less than 1% at 65% relative air humidity)

- Remarkable immunity to nuclear radiation, UV light and biologic contamination

Basalt Fiber Glass Wool:

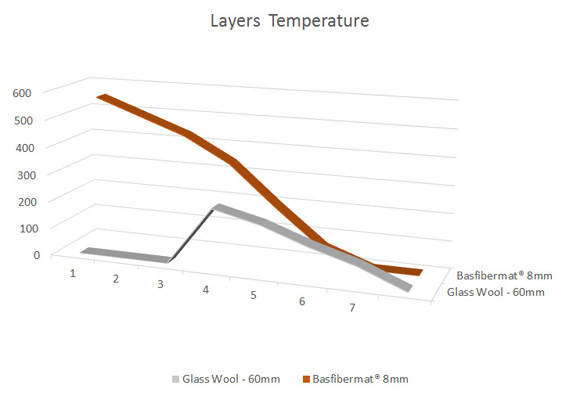

During an experiment Basfibermat® and Glass wool where used for thermal isolation on a pipe with 1500mm diameter preserving the temperature of 550³

The below results show the advantage of Basfibermat® when compared to glass wool which lost proprieties after 300°C;.

Comparison with Glass Wool:

Standard Specifications:

- 6mm, 1/4", 9 lb/ cuft

- 8mm, 1/2", 9 lb/ cuft

- 12mm, 1", 9 lb/ cuft

Download Data Sheet

| Download Non-Woven Technical Data Sheet in .PDF: |  |

| Download Non-Woven Material Safety Data Sheet - MSDS in .PDF: |  |

Contact Us