Reinforcing Mesh

Reinforcing Mesh for application in soil and pavement.

-

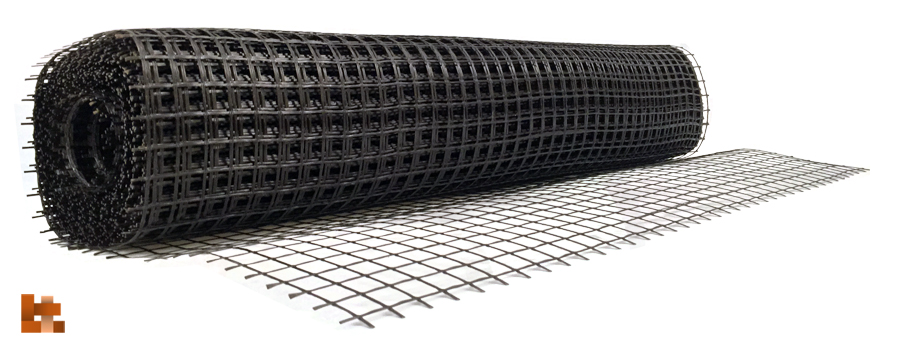

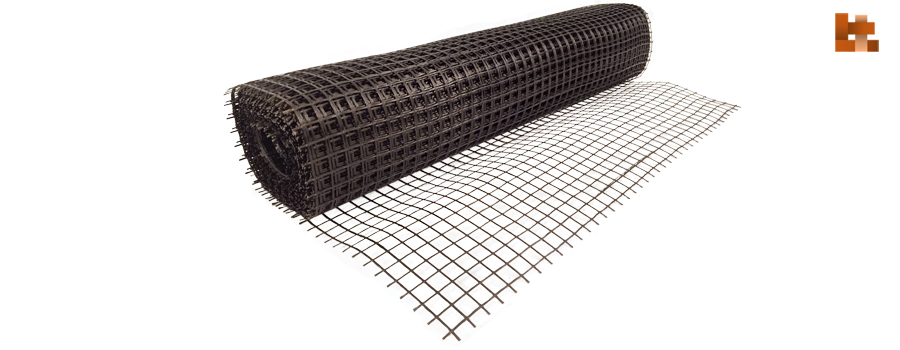

Reinforcing Mesh

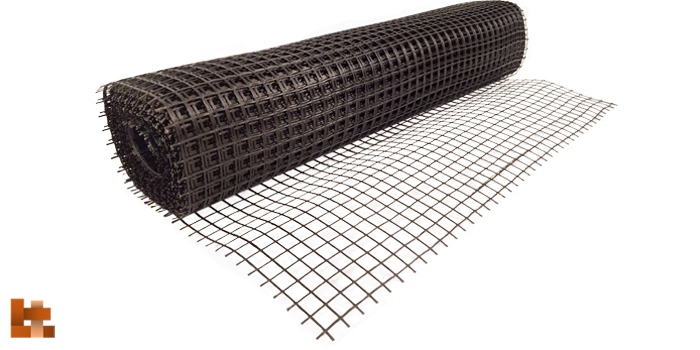

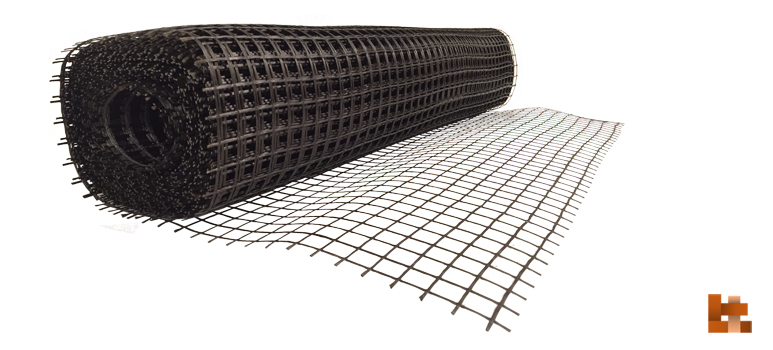

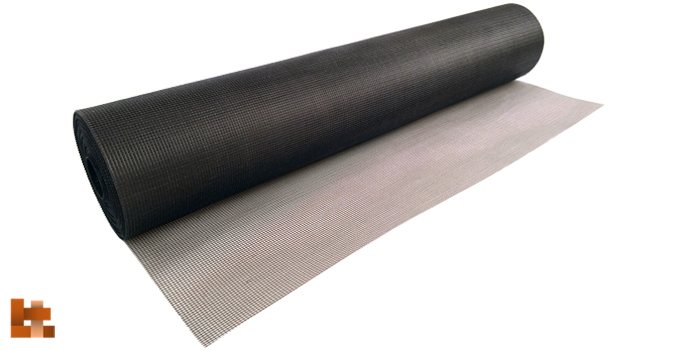

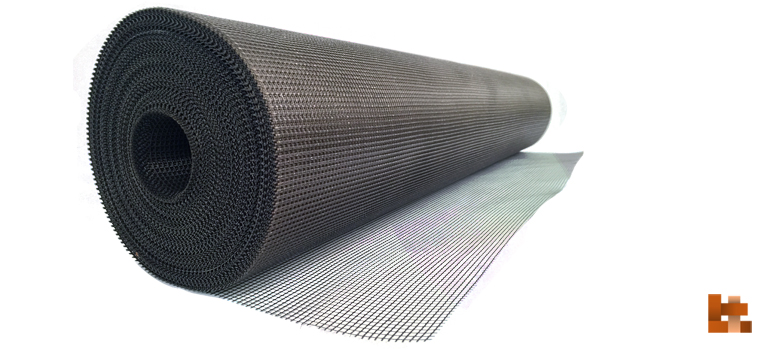

Basfiber® reinforcing mesh is designed for reinforcing road and highway overlays to prolong the pavement lifespan by reducing the effects of reflective cracking caused by traffic loading, age hardening and temperature cycling. Pavement life between maintenance can be prolonged significantly. Basalt reinforcing mesh makes it possible to reduce thickness of asphalt concrete pavement up to 20%.

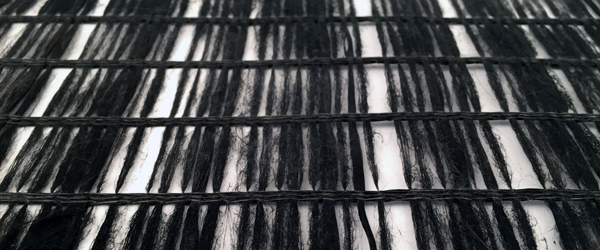

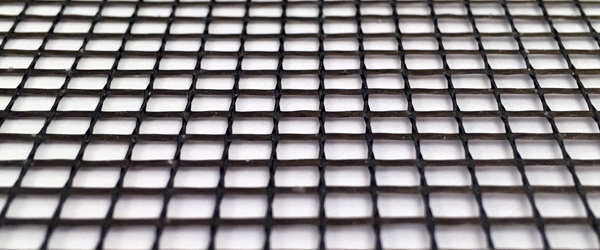

Basalt Fiber Tech offers two different types of basalt reinforcing mesh for roads: with open cell and with closed cell. Basfiber® reinforcing mesh for roads with closed cell is created for quick and simple use. This mesh is produced with texturised basalt roving. Closed cell allows to prevent appearance and stickiness of the bitumen to the drum of the machine.Basfiber®reinforcing mesh with alkali resistant coating were developed to prevent cracks forming in different applications in construction industry as well as for reinforcement of mortars and non load bearing concrete. The higher tensile strength of this product compared to E-glass or steel increases impact resistance and prevents from cracks appearance. This mesh can meet the expectations and strict requirements of most demanding companies from construction market. Our high-performance, alkali-resistant basalt mesh will not rot, rust or corrode, and provides increased strength in different cementitious applications. Thanks to its lightweight, easy install and use basalt mesh will be superior alternatives to steel.Mesh with closed Cells

Mesh with open Cells

-

Download Data Sheet

Download Reinforcing Mesh Technical Data Sheet in .PDF:

Download Assembled Roving Material Safety Data Sheet - MSDS in .PDF:

-

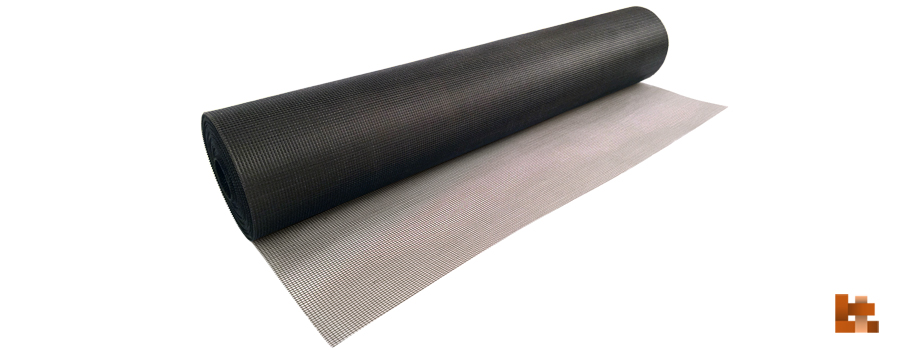

Reinforcing Scrim

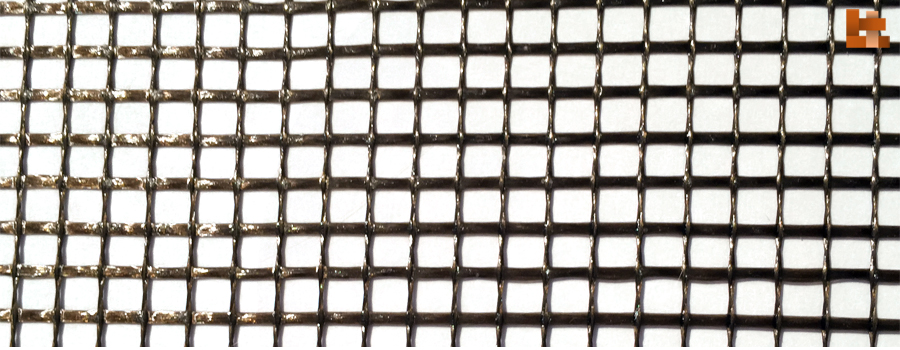

Basalt Fiber Tech offers basalt scrim with a cell size of 3,5 * 3,5 mm. Possible applications for basalt scrim includes but not limited by: reinforcement of the plaster layer for both interior and exterior works, making of self-levelling floors, preventing cracking in gypsum plasterboards, insulation of vessels, tanks, oil and gas pipelines

-

Download Data Sheet

Download Scrim Technical Data Sheet in .PDF:

Download Scrim Material Safety Data Sheet - MSDS in .PDF:

Soil Reinforcements

Increases the Triaxial compressive strength and ductility of soils

Soil can often be regarded as a combination of four basic types gravel sand clay and silt. It generally has low tensile and shear strength and its characteristics may depend strongly on the environment conditions (e.g. dry versus wet).

Soil Reinforcement with geotextile fabrics is a well-established technology and is widely used in road construction for soil reinforcement cement stabilization drainage separation.

Basalt Fibers is Organic and improves the properties of the soil. The shear strength and Compressive strength, bearing capacity, Post peak load strength and the elastic modulus. Basalt Fibers in Soil acts as an organic tensile reinforcing member both in shear and compression and tension. Increases the Triaxial compressive strength and ductility of soil

Basalt Fiber will improve the durability for all types of soils and eliminates the need for frequent regarding. Basalt Fibers will improve the shatter resistance, toughness, and ductility of all soils.

-

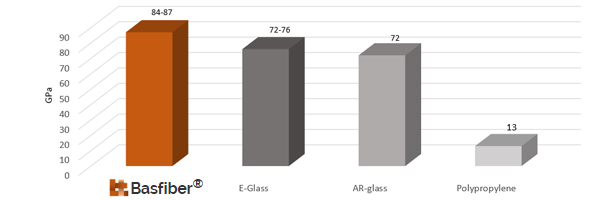

Comparison with Glass Fibers:

Tensile Strength of Single Filament (ASTM D2101)

Tensile Modulus of Single Filament(ASTM D2101)

-

Advantages and benefits:

- Specially developed coating provides good adhesion with concrete to improve tensile strength and increase impact resistance.

- High mechanical strength and modulus.

- High resistance to chemical aggressive environment and in particular high alkali resistance will not allow to appear of rust or corrode.

- Minimizes crack width and spread.

- Easy to install and use. No special equipment is required.

- Extremely low coefficient of heat conductivity significantly reduces heat transfer from building exteriors to interiors and significantly improves energy efficiency.

- Much higher electrical resistance compared to steel.

- Higher mechanical strength and modulus, more resistive to chemical aggressive environment than E-glass mesh.

- The melting point of basalt fibers is 1450°C. Typical paving temperatures will not cause any loss of strength or distortion which may occur with synthetic material.

- Lower application temperature than for synthetic material that is especially important for north regions.

- Lower elongation before brake than for synthetic material.

- Easily milled using typical milling equipment. Does not stretch and pull as polymer meshes.

- No special equipment is required to install the reinforcement.

- Basalt mesh is environment friendly and based on naturally occurring material that is found worldwide

Contact Us